- Home

-

Abouts

-

Products

- Plate Shears Series

- Bending Machine Series

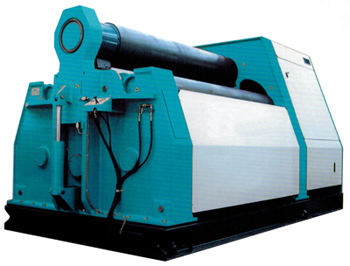

- Rolling Machine Series

- Mechanical press

- Hydraulic press

- High performance press

- Optical fiber laser cutting machine

- Combined punching and shearing machine

- Profile bender pipe bender

- Grooving machine series

- Tool and mold series

- Cold-Frame Bender

- Shearing machine

- leveling machine

- Biting machine

- Plate rolling machine

-

News

-

Partner

-

Contacts

-

CN

CN

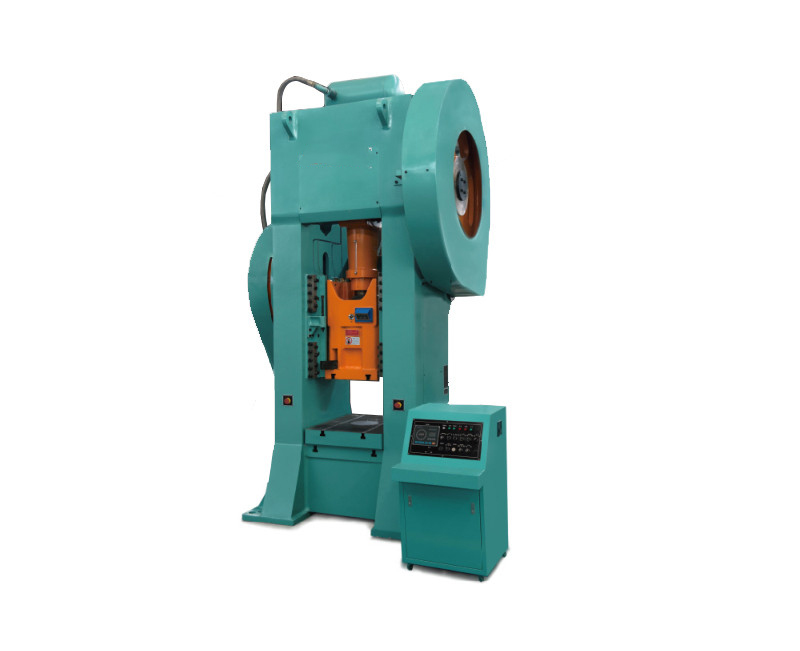

JA31 Series closed single point press

Send Email

Product Overview:

JA31 series closed single point press is an upgraded product of our company in the traditional type. The product is stable and durable, with features such as large capacity generation point, large mold space, and can be combined with peripheral automation for production. Easy to operate and maintain, suitable for processes such as blanking, blanking, bending, stretching, correcting, and cold stamping, as well as functions such as deep drawing, strong blanking, and extrusion.

Performance characteristics:

1. The Q235A steel plate welded structure of the fuselage has a linear design, uniform stress, good rigidity of the entire machine, and beautiful appearance; Use low temperature tempering to remove stress.

The crankshaft is laid horizontally, and the transmission system is placed on both sides of the machine body. The structure is compact, the layout is reasonable, and the transmission is stable.

3. The pneumatic friction clutch is adopted, with reliable performance and sensitive action.

The 8-sided guide rail is used for guiding, which ensures stable operation and high accuracy, and extends the service life of the mold.

The slider is equipped with a hydraulic overload safety device to ensure the safety of the press.

6. The pneumatic double balance structure is adopted to balance the weight of the slider and the upper mold, ensuring smooth operation and improving stamping accuracy.

7. The main lubrication adopts a lubrication system that combines centralized and fixed-point oil supply methods to ensure that each lubrication part has sufficient oil quantity.

8. Externally supported frame, with concentrated impact pressure, ensures stability and safety of operation.

9. It can be equipped with peripheral automatic production product devices to achieve automatic stamping production and improve production efficiency.

10. Optional photoelectric protection device to ensure the personal safety of the operator.

Main Technical Parameters of JA31 Series Closed Single Point Press

Technical Parameter | unit | JA31- 125 | JA31- 160 | JA31- 200 | JA31- 250 | JA31- 315 | JA31- 400 | JA31- 500 | JA31- 630 | JA31- 800 | JA31- 1000 | |

Sliding block nominal pressure | kn | 1250 | 1600 | 2000 | 2500 | 3150 | 4000 | 5000 | 6300 | 8000 | 10000 | |

Ability occurrence location | m | 8 | 10 | 12 | 12 | 13 | 13 | 15 | 15 | 15 | 15 | |

Slide stroke | mm | 165 | 180 | 210 | 250 | 250 | 270 | 320 | 350 | 350 | 380 | |

Stroke times | s.p.m | 40 | 35 | 35 | 30 | 27 | 27 | 20 | 15 | 12 | 12 | |

Maximum enclosed height | mm | 515 | 630 | 690 | 650 | 665 | 730 | 800 | 920 | 950 | 1040 | |

Closed height adjustment amount | mm | 90 | 90 | 120 | 125 | 125 | 125 | 130 | 150 | 150 | 160 | |

Distance between columns | mm | 745 | 770 | 830 | 900 | 900 | 960 | 1100 | 1250 | 1350 | 1500 | |

Workbench size | around | mm | 820 | 880 | 950 | 1000 | 1100 | 1200 | 1300 | 1500 | 1600 | 1700 |

about | mm | 700 | 740 | 800 | 860 | 860 | 920 | 1050 | 1200 | 1350 | 1450 | |

thickness | mm | 115 | 130 | 140 | 150 | 165 | 180 | 200 | 220 | 230 | 240 | |

diameter | mm | 180 | 220 | 240 | 280 | 300 | 300 | 300 | 375 | |||

around | mm | 460 | 460 | 530 | 650 | 650 | 700 | 800 | 900 | 1000 | 1100 | |

左右 | mm | 500 | 500 | 540 | 600 | 600 | 650 | 750 | 850 | 950 | 1050 | |

Mold handle hole size | diameter | mm | 65 | 65 | 70 | 80 | 80 | 80 | 80 | 80 | ||

depth | mm | 85 | 85 | 90 | 110 | 110 | 120 | 140 | 160 | |||

External dimensions | around | mm | 1715 | 1860 | 2025 | 2245 | 2440 | 2515 | 2850 | 2585 | 3005 | |

about | mm | 1915 | 2060 | 2215 | 2445 | 2685 | 2775 | 3365 | 4230 | 3775 | ||

tall | mm | 3515 | 3735 | 4135 | 4515 | 4615 | 4790 | 5400 | 6410 | 6130 | ||

Motor Power | kw | 11-4p | 15-4p | 22-4p | 30-4p | 37-4p | 45-4p | 55-4p | 55-4p | 90-4p | ||

weight | kg | 8000 | 10100 | 15500 | 17817 | 24200 | 28240 | 40100 | 56900 | |||

Standard configuration

DRY CLUTCH | Hydraulic overload protection device | Electric butter lubrication device | Manual thin oil lubrication device |

Sliding block and upper mold balancing device | Electronic crankshaft angle indicator | Electronic cam controller | Electric slider adjustment device |

Programmable controller | Upper material removal device of slider | Air source quick connector | Dual solenoid valve |

Mobile Two Hand Console | Crash Pad | Air blowing material | Mobile electrical control box |

Optional configuration: (user selection, should be specified in the contract)

Wet clutch brake | Pneumatic mold pad device | photoelectric safety device | QUICK DIE CHANGE SYSTEM |

Foot switch | Automatic feeding output shaft | Preset Counter | frequency converter |

Email Consultation