- 网站首页

-

Abouts

-

Products

- Plate Shears Series

- Bending Machine Series

- Rolling Machine Series

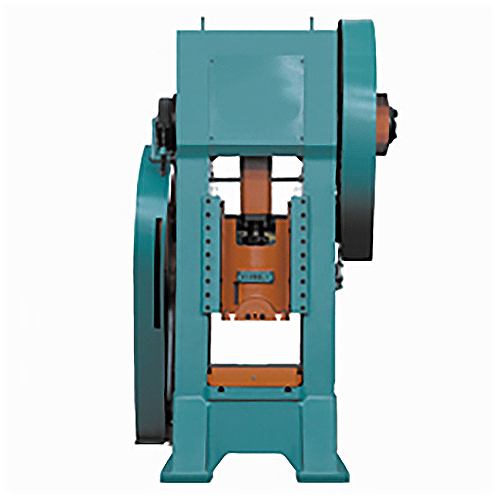

- Mechanical press

- Hydraulic press

- High performance press

- Optical fiber laser cutting machine

- Combined punching and shearing machine

- Profile bender pipe bender

- Grooving machine series

- Tool and mold series

- Cold-Frame Bender

- Shearing machine

- leveling machine

- Biting machine

- Plate rolling machine

-

News

-

Partner

-

Contacts

-

EN

EN

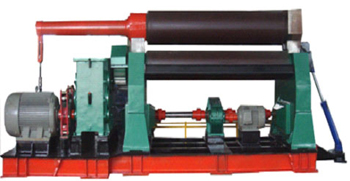

W11S (for ship use) Plate Roll

Send Email

Performance Characteristics:

W11s series of ship-use hydraulic upper roll universal three-roll plate roll is a large plate roll developed, designed and manufactured by our company. It has pre-bend function, the vertical lift and horizontal move of the upper roll is hydraulic driven, with simple structure, convenient to process and install. The rack, cross beam and body structure of the machine consist of upper roll mechanism, lower roll, horizontal move mechanism, roll support mechanism, main gear, tilting device, racks at left and right sides and chassis. The upper roll mechanism: mainly consist of main oil cylinder, upper roll bearing seat, upper roll and double row self-aligning bearing. The two main oil cylinders provide the necessary pressure for rolling plate. Lower roll and horizontal move mechanism: the lower roll mechanism consists of lower roll, lower roll bearing seat, lower roll input gear and lower roll sliding bearing. The main transmission of the lower roll provides the drive, via main transmission out-put gear, lower roll input gear and opening transmission torque to the lower roll. The horizontal move mechanism consists of horizontal move motor, worm gear case and worm gear. The power of horizontal displacement is provided by horizontal displacement motor, and the horizontal displacement of the upper roll is transmitted by worm gear box, worm gear and wire rod and mother mechanism, to realize asymmetric rolling of the plate. Roll support mechanism: consists of wire rod and mother mechanism, inclined wedge mechanism and support roll. The support roll can be adjusted up and down, according to the loading capacity of rolling plate specifications. Main gear: consists of main motor, vee belt, cylinder gear reducer and electric hydraulic pole pushing brake. The main transmission can rotate positively and reversely, providing power for rolling plate. Tilting device: consists of ram and tilting oil cylinder. The tilting of the tilting device makes it possible to take out the product. Fixed, tilted side rack and chassis: are steel plate welding structure, after welding it's annealed to remove stress and receive shot blast treatment.

Main Technical Parameters of W11S (Ship-use) Plate Roll

Specifications and Model | Maximum Roll Plate Thickness | Maximum Roll Plate Width | Plate Roll Speed | Minimum Diameter at Full Load | Diameter of Upper Roll | Diameter of Lower Roll | Diameter of Upper | Diameter of Lower Support Roll | Distance between Centers of Two Lower Rolls (mm) | Main Motor Power | Hydraulic Motor Power |

20×8000 | 20 | 8000 | 4 | 5000 | 380 | 320 | 380 | 320 | 470 | 75 | 30 |

25×10000 | 25 | 10000 | 4 | 6000 | 500 | 360 | 380 | 360 | 540 | 75 | 30 |

20×10000 | 20 | 10000 | 4 | 8000 | 600 | 380 | 400 | 400 | 600 | 110 | 45 |

25×12000 | 25 | 12000 | 4 | 10000 | 650 | 420 | 420 | 400 | 750 | 130 | 45 |

邮件咨询