- 网站首页

-

Abouts

-

Products

- Plate Shears Series

- Bending Machine Series

- Rolling Machine Series

- Mechanical press

- Hydraulic press

- High performance press

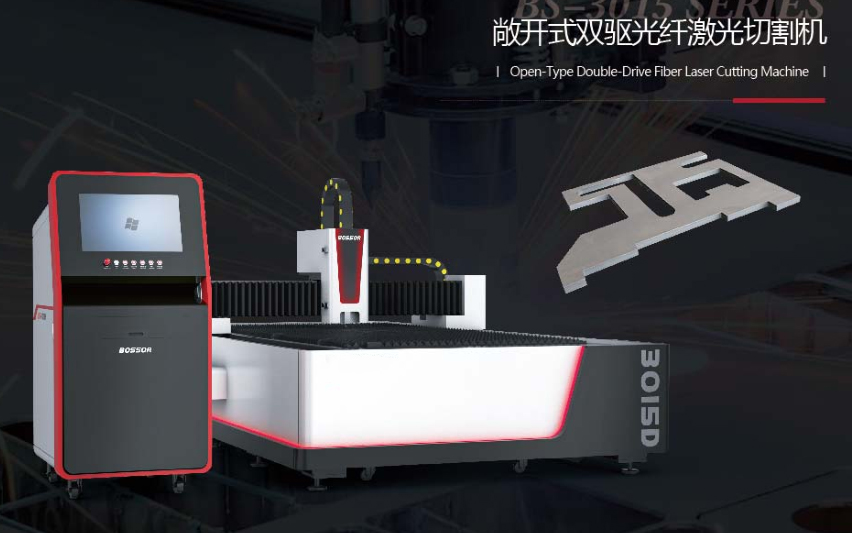

- Optical fiber laser cutting machine

- Combined punching and shearing machine

- Profile bender pipe bender

- Grooving machine series

- Tool and mold series

- Cold-Frame Bender

- Shearing machine

- leveling machine

- Biting machine

- Plate rolling machine

-

News

-

Partner

-

Contacts

-

EN

EN

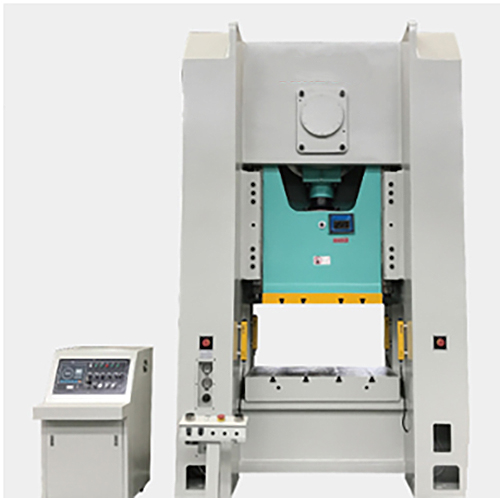

JH31 closed single point press

Send Email

Performance characteristics:

1. The welded structure of the steel plate of the fuselage has good rigidity. The stress is removed by means of trolley type electric furnace annealing or vibration aging, and the deformation is small; The closed structure eliminates the angular deformation of the open press and greatly improves the processing accuracy of the stamping parts and the service life of the die.

2. The crankshaft is placed longitudinally, with short fulcrum distance, compact structure and reasonable layout; The transmission gear runs in oil, with low noise and wear.

3. Pneumatic friction clutch brake, mechanical interlock, safe and reliable, low noise, friction plate is not easy to wear; Domestic clutch of Shanghai "Dingjie" brand or Italian "OMPI" brand shall be selected; The wet clutch is also provided according to the special needs of users.

4. Imported pneumatic pump with good stability and sensitive action response; External oil tank, easy to maintain.

5. The slider guide rail is six sided, long, and the machine tool has high operation accuracy.

6. The lubricating system adopts imported electric grease pump for automatic fixed-point lubrication, and is equipped with a progressive distributor. The oil supply time and amount are controlled by the PLC system, and the oil circuit is blocked for automatic alarm indication.

7. The mold mounting height is electrically adjusted, which is easy to use. It is equipped with a digital mold height indicator, and the display accuracy is+0.1mm.

8. Equipped with pneumatic balance cylinder to balance the weight of sliding block and upper mold to ensure smooth operation of the press.

9. The electrical system is controlled by French "Schneider" brand or Japanese "Hequan" programmable controller (PLC), with emergency stop, inching, single time and continuous operation modes; The main electrical components are French "Schneider" brand, with reliable performance.

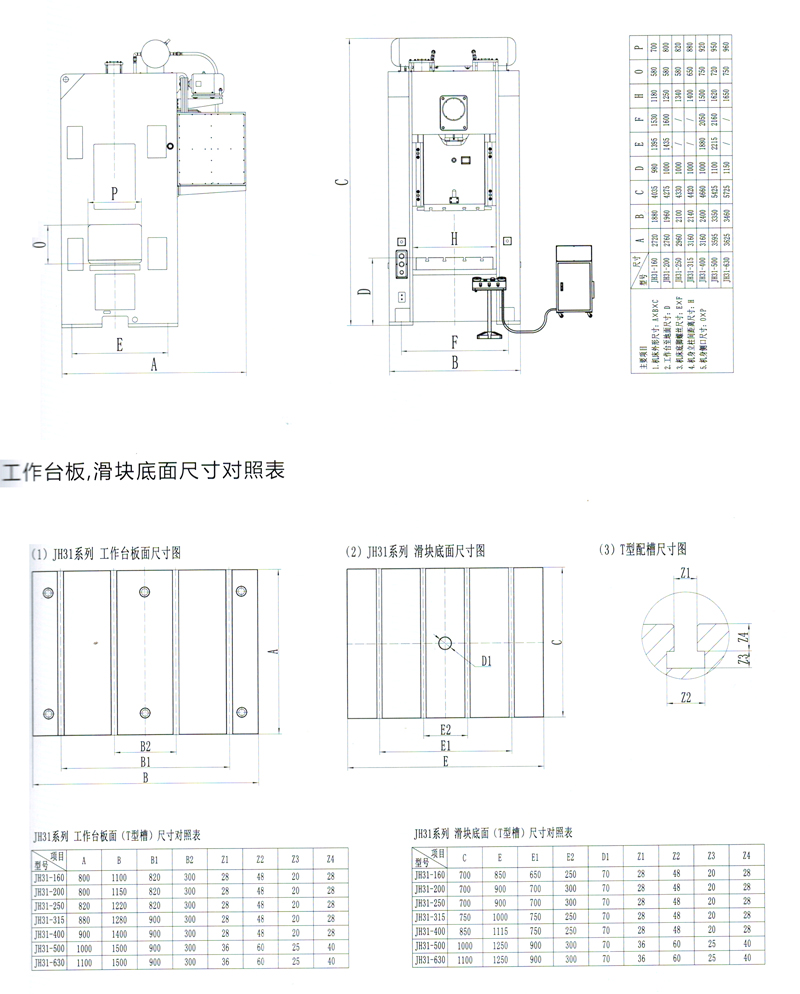

Main Technical Parameters of JH31 Closed Single Point Press

Technical Parameter | 单位 | JH31-80A | JH31-160 | JH31-200 | JH31-250 | JH31-315 | JH31-400 | JH31-500 | JH31-630 | JH31-800 | |

Sliding block nominal pressure | KN | 800 | 1600 | 2000 | 2500 | 3150 | 4000 | 5000 | 6300 | 8000 | |

Ability occurrence location | mm | 4 | 6 | 7 | 7 | 7 | 8 | 9 | 10 | 12 | |

Slide stroke | mm | 120 | 200 | 250 | 250 | 250 | 280 | 320 | 350 | 380 | |

Stroke times | 次/min | 100 | 45/30-45 | 40/25-40 | 40/25-40 | 35/20-35 | 30/20-30 | 25 | 15-20 | 10-15 | |

Maximum enclosed height | mm | 450 | 400 | 450 | 500 | 550 | 660 | 650 | 700 | 750 | |

Closed height adjustment amount | mm | 80 | 100 | 110 | 120 | 120 | 120 | 130 | 130 | 150 | |

Distance between columns | mm | 1800 | 1180 | 1250 | 1340 | 1400 | 1500 | 1620 | 1650 | 1650 | |

Distance from workbench to ground | mm | 900 | 980 | 1000 | 1000 | 1000 | 1000 | 1100 | 1150 | 1200 | |

Workbench size | about | mm | 1600 | 1100 | 1150 | 1220 | 1280 | 1400 | 1500 | 1500 | 1600 |

around | mm | 600 | 800 | 800 | 820 | 880 | 900 | 1000 | 1100 | 1150 | |

thickness | mm | 140 | 160 | 180 | 190 | 200 | 200 | 250 | 250 | 260 | |

Bottom size of slider | about | mm | 850 | 850 | 900 | 900 | 1000 | 1115 | 1250 | 1300 | 1300 |

around | mm | 460 | 700 | 700 | 700 | 750 | 850 | 1000 | 1000 | 1000 | |

Body side port size | up and down | mm | 400 | 580 | 580 | 580 | 650 | 750 | 720 | 750 | 750 |

around | mm | 420 | 700 | 800 | 820 | 880 | 920 | 950 | 960 | 960 | |

Mold handle hole size | diameter | mm | 70 | 70 | 70 | 70 | 70 | 70 | 70 | ||

depth | mm | 90 | 95 | 90 | 90 | 100 | 120 | ||||

External dimensions | about | mm | 2360 | 1880 | 1960 | 2100 | 2140 | 2400 | 3350 | 3460 | 3460 |

around | mm | 1650 | 2720 | 2760 | 2960 | 3160 | 3160 | 3595 | 3625 | 3625 | |

tall | mm | 2900 | 4035 | 4275 | 3880 | 4000 | 4660 | 5425 | 5725 | 6350 | |

Motor power (fixed/variable) | KW | 7.5/11 | 15/18.5 | 18.5/22 | 22/30 | 30/37 | 37/45 | 37-4P | 55-4P | 75-4P | |

weight | kg | 9500 | 16000 | 19400 | 29000 | 33500 | 40500 | 43100 | |||

Note: If the parameters in this table are inconsistent with the machine tool data, the actual data of the machine tool shall prevail. The Company reserves the right of final interpretation.

Standard configuration:

Dry clutch, hydraulic overload protection device, electric grease lubrication device, manual thin oil lubrication device, sliding block and upper mold balancing device, electronic crankshaft angle indicator, electronic cam controller, electric sliding block adjusting device, programmable controller, sliding block upper stripping device, air source quick connector, dual solenoid valve, movable two handed operation platform shock pad, air blowing, frequency converter, Movable electrical control box.

Selected configuration: (selected by the user, which shall be indicated in the contract)

Wet clutch brake, pneumatic mold pad device, photoelectric safety device, quick mold change device, foot switch, automatic feeding output shaft, preset counter

邮件咨询