- Home

-

Abouts

-

Products

- Plate Shears Series

- Bending Machine Series

- Rolling Machine Series

- Mechanical press

- Hydraulic press

- High performance press

- Optical fiber laser cutting machine

- Combined punching and shearing machine

- Profile bender pipe bender

- Grooving machine series

- Tool and mold series

- Cold-Frame Bender

- Shearing machine

- leveling machine

- Biting machine

- Plate rolling machine

-

News

-

Partner

-

Contacts

-

CN

CN

W12 Four-roller Plate Roll

Send Email

Performance Characteristics:

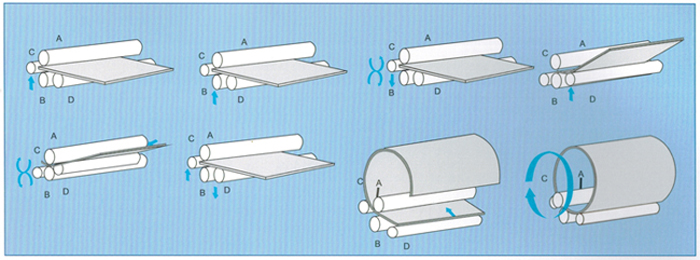

W12 (nc, cnc) series CNC four-roller plate roll can achieve one-time feeding of metal plate, without reversing its end to end, the plate ends can be pre-bended and formed by rolling. Moreover, among all the bending machines, its surplus straight edge is the smallest. For this series of plate roll: the top roll and bottom roll are both drive roller, driven by hydraulic motor, the side roll is driven roller, driven by the force of friction between the steel plate and the rollers to spin. The position of top roll is fixed, while the bottom roll and side roll make lifting motion driven by the parallel cylinders on its both sides. The turnover and reset of the top roll unloading header is driven by the cylinder. In order to improve the rigidity of bottom roll, supporting roll is installed in the middle of the bottom roll, whose lifting is driven by cylinder.

This series of plate roll have the following outstanding features:

The work roll uses the self-aligning roller bearing for rolling mill, and the frictional resistance is low, so that the power loss is small, the service life is longer and the energy conservation is low.

Controlling and leveling of the synchronous lifting and conical bending inclination amount is automatically realized by CNC system, with high control precision.

Our CNC system is at leading level in domestic China, which has functions like on screen display, rolling computation, program control, process parameters storage, software protection and failure alarm.

Main Technical Parameters of W12 Four-roller Plate Roll

Specifications and Model | Maximum pre bending thickness | Maximum Roller Plate Thickness | Maximum Roller Plate Width | Plate Yielding Limit | Plate Rolling Speed | Diameter of Top Roll | Diameter of Bottom Roll | Diameter of Side Roll | Hydraulic Motor Power |

TYPE | (mm) | (mm) | (mm) | (mpa) | (m/min) | (mm) | (mm) | (mm) | (KW) |

6×2000 | 6 | 6 | 2000 | 265 | 5.5 | 180 | 180 | 145 | 5.5 |

6×2500 | 6 | 6 | 2500 | 265 | 5 | 210 | 210 | 165 | 7.5 |

8×2000 | 6 | 8 | 2000 | 265 | 5 | 215 | 215 | 165 | 11 |

8×2500 | 6 | 8 | 2500 | 265 | 5 | 230 | 230 | 180 | 11 |

12×2000 | 10 | 12 | 2000 | 265 | 5 | 260 | 260 | 200 | 18.5 |

12×2500 | 10 | 12 | 2500 | 265 | 5 | 280 | 280 | 220 | 18.5 |

16×2000 | 12 | 16 | 2000 | 265 | 5 | 280 | 280 | 220 | 18.5 |

16×2500 | 12 | 16 | 2500 | 265 | 5 | 330 | 330 | 260 | 22 |

16×3200 | 12 | 16 | 3200 | 265 | 5 | 360 | 360 | 280 | 30 |

20×2000 | 16 | 20 | 2000 | 265 | 5 | 330 | 330 | 260 | 22 |

20×2500 | 16 | 20 | 2500 | 265 | 5 | 360 | 360 | 380 | 30 |

25×2000 | 16 | 25 | 2000 | 265 | 5 | 360 | 360 | 280 | 30 |

25×2500 | 20 | 25 | 2500 | 265 | 4.5 | 410 | 400 | 320 | 37 |

30×2000 | 25 | 30 | 2000 | 265 | 4.5 | 410 | 400 | 320 | 37 |

30×2500 | 25 | 30 | 2500 | 265 | 4.5 | 470 | 470 | 390 | 37 |

30×3000 | 25 | 30 | 3000 | 265 | 4.5 | 560 | 520 | 420 | 45 |

40×2500 | 35 | 40 | 2500 | 265 | 4.5 | 560 | 520 | 420 | 45 |

40×3000 | 36 | 40 | 3000 | 265 | 4 | 650 | 580 | 480 | 55 |

50×2500 | 40 | 50 | 2500 | 265 | 4 | 650 | 620 | 500 | 55 |

50×3000 | 40 | 50 | 3000 | 265 | 3.5 | 720 | 650 | 520 | 55 |

60×3000 | 50 | 60 | 3000 | 265 | 3.5 | 750 | 710 | 560 | 75 |

70×3000 | 60 | 70 | 3000 | 265 | 3 | 750 | 720 | 600 | 75 |

80×3000 | 70 | 80 | 3000 | 265 | 3 | 800 | 780 | 620 | 75 |

90×3000 | 80 | 90 | 3000 | 265 | 3 | 840 | 820 | 660 | 90 |

100×3000 | 85 | 100 | 3000 | 265 | 3 | 900 | 880 | 700 | 90 |

Email Consultation