- Home

-

Abouts

-

Products

- Plate Shears Series

- Bending Machine Series

- Rolling Machine Series

- Mechanical press

- Hydraulic press

- High performance press

- Optical fiber laser cutting machine

- Combined punching and shearing machine

- Profile bender pipe bender

- Grooving machine series

- Tool and mold series

- Cold-Frame Bender

- Shearing machine

- leveling machine

- Biting machine

- Plate rolling machine

-

News

-

Partner

-

Contacts

-

CN

CN

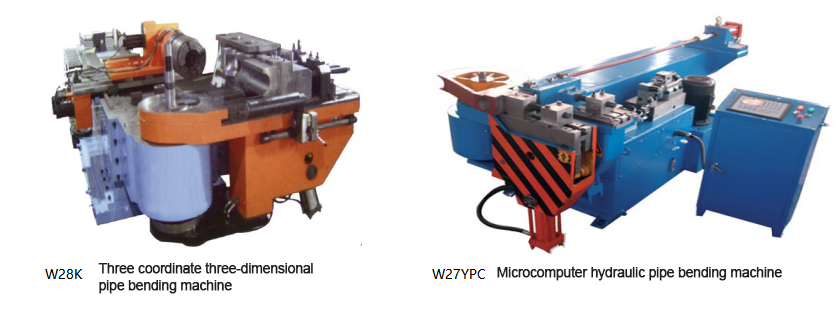

Hydraulic pipe bender series

Send Email

The reinforcing rib of the machine tool head and the machine body is designed and annealed to eliminate internal stress. The overall strength and rigidity are sufficient to prevent permanent deformation.

● The transmission spindle is inserted directly from the upper part of the machine head during assembly, with accurate installation and convenient maintenance. The bent tube spindle and the drive sprocket are integrally forged and machined, integrally hobbed, keyless connection, evenly stressed, driven by two oil cylinders, and the hydraulic system automatically restricts and buffers the rotary arm before it approaches the angle value set for bending. The bending accuracy is greatly improved, and throttling buffer is set near the starting point of quick reset, which greatly improves the reset accuracy and working efficiency (it is the only manufacturer that uses this structure in China).

● The clamping system adopts a sinking four-bar lifting force amplifier. After bending the finished product, the chuck will sink into the rotary arm, which is more convenient for loading and unloading and space bending (the finished product will fall naturally under gravity, which is convenient for pipe unloading).

● The microcomputer controller can preset 16 kinds of bending angles, and can use the foot switch to complete the entire process flow at one time, including hydraulic clamping, hydraulic pressing, hydraulic bending, hydraulic auxiliary pushing, hydraulic core pulling, and wrinkle prevention device with special accessories. Six oil cylinders (trolley feeding and space angle functions can be added).

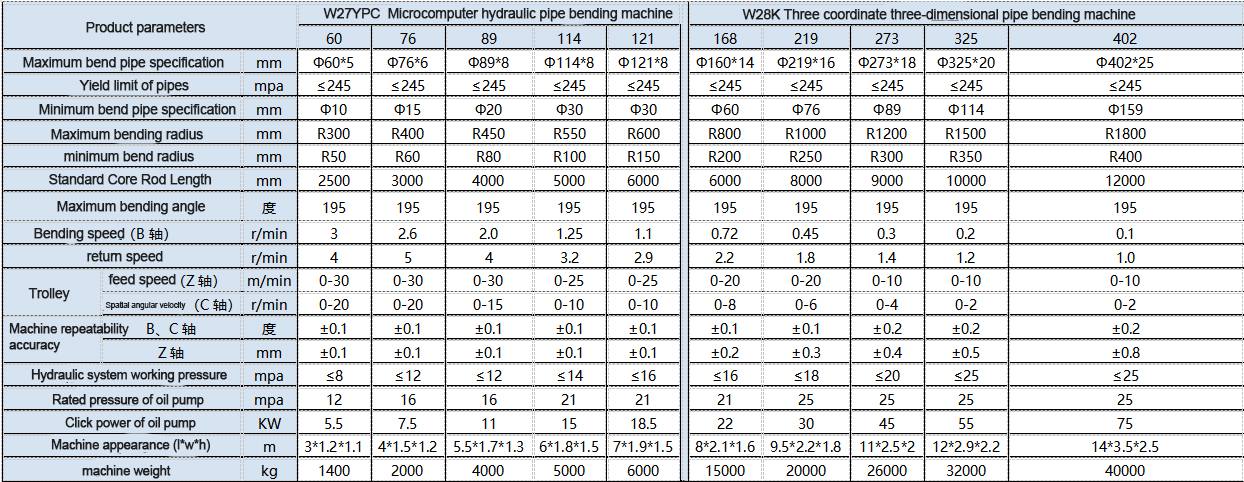

Note: If the parameters in this table are inconsistent with the machine tool data, the actual data of the machine tool shall prevail. The Company reserves the right of final interpretation.

Email Consultation