- 网站首页

-

Abouts

-

Products

- Plate Shears Series

- Bending Machine Series

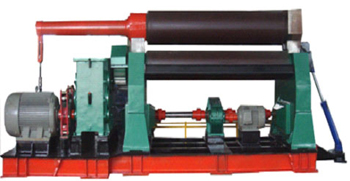

- Rolling Machine Series

- Mechanical press

- Hydraulic press

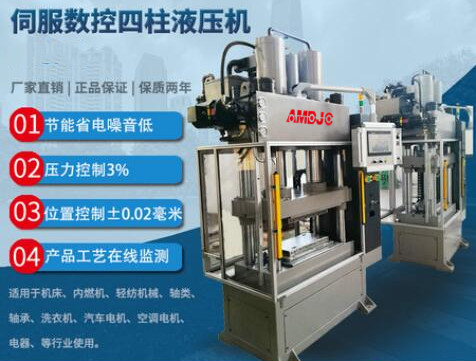

- High performance press

- Optical fiber laser cutting machine

- Combined punching and shearing machine

- Profile bender pipe bender

- Grooving machine series

- Tool and mold series

- Cold-Frame Bender

- Shearing machine

- leveling machine

- Biting machine

- Plate rolling machine

-

News

-

Partner

-

Contacts

-

EN

EN

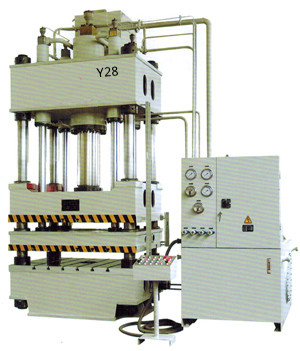

Y32 series four column hydraulic press

Send Email

Performance characteristics:

This machine is applicable to the pressing process of plastic materials, such as blanking, bending, flanging, sheet drawing, etc. It can also be used in correction, press mounting, grinding wheel forming, cold extrusion metal parts forming, plastic products and powder products forming.

The machine has an independent power mechanism and electrical system, and adopts centralized button control, which can realize three operation modes of adjustment, manual and semi-automatic.

The working pressure, pressing speed and stroke range of the machine can be adjusted according to the process requirements. It can also complete two process modes of constant pressure and fixed range forming. The process mode of constant pressure forming has pressure maintaining and automatic return action after pressing.

Yq32 four column hydraulic press has the functions of ejection, delay and automatic return in addition to the above functions.

Low power consumption, high sealing performance, lower production cost.

Parameter table of Y32 series four column hydraulic press:

Parameter | unit | Four column hydraulic press | |||||||||||||||||

40 | 63 | 100 | 100B | 100C | 160A | 160B | 200 | 315 | 400 | 500 | 500C | 630 | 800 | 1000 | 1250 | 1600 | |||

Nominal force | KN | 400 | 630 | 1000 | 1000 | 1000 | 1600 | 1600 | 2000 | 3150 | 4000 | 5000 | 5000 | 6300 | 8000 | 10000 | 12500 | 16000 | |

ejection force | KN | 120 | 1902 | 190 | 190 | 190 | 400 | 400 | 400 | 630 | 630 | 1000 | 1000 | 1000 | 1600 | 2000 | 2000 | 2000 | |

Maximum working pressure of liquid | mpa | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | |

Slide stroke | mm | 450 | 500 | 600 | 600 | 600 | 700 | 700 | 700 | 800 | 800 | 900 | 900 | 900 | 900 | 900 | 900 | 900 | |

ejection stroke | mm | 150 | 200 | 200 | 200 | 200 | 200 | 200 | 250 | 300 | 300 | 350 | 350 | 350 | 450 | 450 | 450 | 450 | |

Maximum distance from the lower plane of the slider to the workbench surface | mm | 700 | 800 | 900 | 900 | 900 | 1000 | 1000 | 1100 | 1250 | 1300 | 1500 | 1500 | 1500 | 1500 | 1600 | 1600 | 1600 | |

Slide travel speed | Empty journey down | mm/s | 80 | 220 | 22 | 120 | 220 | 100 | 100 | 100 | 100 | 120 | 100 | 100 | 80 | 80 | 80 | 80 | 80 |

Work | mm/s | 25 | 16 | 14 | 14 | 14 | 12 | 12 | 8 | 6-8 | 5-7 | 5 | 5 | 10 | 8 | 10 | 6-10 | 6-10 | |

return trip | mm/s | 80 | 150 | 120 | 120 | 120 | 60 | 60 | 52 | 60 | 45 | 60 | 60 | 60 | 50 | 50 | 45 | 40 | |

Workbench size | about | mm | 500 | 580 | 720 | 720 | 720 | 680 | 1000 | 1000 | 1260 | 1240 | 1400 | 2450 | 1500 | 1500 | 1530 | 1700 | 2000 |

Before and after | mm | 460 | 500 | 580 | 580 | 58/0 | 620 | 800 | 900 | 1200 | 1200 | 1400 | 1480 | 1500 | 1400 | 1600 | 1600 | 1600 | |

Machine dimensions | about | mm | 2000 | 2400 | 2500 | 2500 | 2500 | 2700 | 2800 | 3100 | 3235 | 3235 | 4060 | 6500 | 4200 | 4800 | 5250 | 5250 | 5800 |

Before and after | mm | 1300 | 1400 | 1500 | 1500 | 1500 | 1700 | 1700 | 1800 | 2060 | 2200 | 3535 | 3800 | 4200 | 4000 | 3800 | 3800 | 4000 | |

Ground height | mm | 2600 | 3100 | 2950 | 2950 | 3150 | 3400 | 3400 | 3500 | 4295 | 4500 | 4995 | 4740 | 5600 | 6000 | 5800 | 6000 | 6200 | |

total power | KW | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 11 | 11 | 15 | 22 | 22 | 44 | 44 | 44 | 60 | 75.5 | 75.5 | 75.5 | |

machine weight | Kg | 1500 | 3800 | 4000 | 4000 | 4000 | 5000 | 6200 | 14000 | 14000 | 17500 | 28000 | 38000 | 38000 | 41000 | 48000 | 60000 | 82000 | |

Note: If the parameters in this table are inconsistent with the machine tool data, the actual data of the machine tool shall prevail. The Company reserves the right of final interpretation.

邮件咨询