- 网站首页

-

Abouts

-

Products

- Plate Shears Series

- Bending Machine Series

- Rolling Machine Series

- Mechanical press

- Hydraulic press

- High performance press

- Optical fiber laser cutting machine

- Combined punching and shearing machine

- Profile bender pipe bender

- Grooving machine series

- Tool and mold series

- Cold-Frame Bender

- Shearing machine

- leveling machine

- Biting machine

- Plate rolling machine

-

News

-

Partner

-

Contacts

-

EN

EN

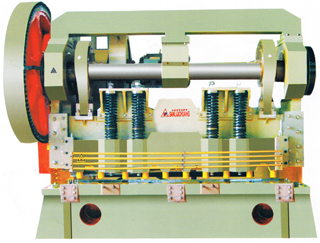

QC11Y/K Hydraulic Cartridge Digital Readout (CNC) Plate Shear

Send Email

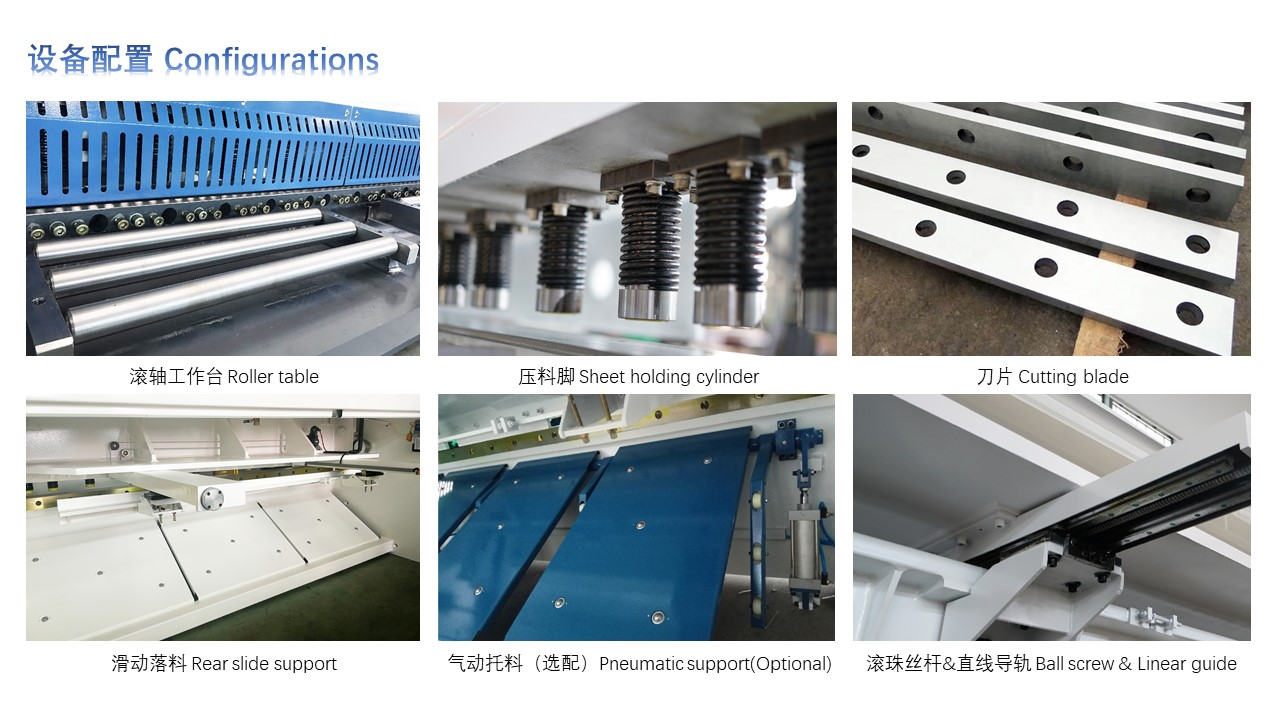

1. Adopting a fully welded steel plate structure, vibration eliminates stress, and has good rigidity and stability. 2. Adopting ball screw and linear guide, servo control, high positioning accuracy.

3. The serial oil cylinder ensures that the cutting angle of the machine tool does not change during cutting.

4. The accumulator returns smoothly and quickly.

5. Automatic adjustment of blade clearance, accurate, fast, and convenient.

6. The cutting angle can be adjusted to reduce the distortion and deformation of the sheet metal.

7. Electric rear gear shift and position display, convenient and accurate.

8. Roller type workbench reduces sheet metal scratches and reduces friction.

9. E21S or numerical control systems such as DA41, DA52S, DAC316S, DAC360S, etc.

Technical parameters of QC11K hydraulic gate type CNC shearing machine

model | Can be cut Plate thickness (mm) | Can be cut Board width (mm) | Throat and mouth depth (mm) | Rear blocking material distance (mm) | shear angle | trip frequency (min-1) | electric machinery power (KW) | External dimensions(mm) | weight(T) |

6×2500 | 6 | 2500 | 80 | 600 | 0.5-1.3 | 14 | 7.5 | 3100×1725×1960 | 5.3 |

6×3200 | 6 | 3200 | 80 | 600 | 0.5-1.3 | 12 | 7.5 | 3650×1750×1980 | 6.5 |

6×4000 | 6 | 4000 | 80 | 600 | 0.5-1.3 | 10 | 7.5 | 4650×1780×2075 | 7.5 |

6×5000 | 6 | 5000 | 80 | 600 | 0.5-1.3 | 8 | 7.5 | 5650×1830×2250 | 10.5 |

6×6000 | 6 | 6000 | 80 | 600 | 0.5-1.3 | 8 | 7.5 | 6650×1890×2380 | 15.2 |

8×2500 | 8 | 2500 | 80 | 600 | 0.5-1.3 | 14 | 7.5 | 3100×1725×1960 | 6 |

8×3200 | 8 | 3200 | 80 | 600 | 0.5-1.3 | 12 | 7.5 | 3850×1750×1980 | 6.8 |

8×4000 | 8 | 4000 | 80 | 600 | 0.5-1.3 | 10 | 7.5 | 4650×1850×2075 | 8.5 |

8×5000 | 8 | 5000 | 80 | 600 | 0.5-2 | 7 | 15 | 5850×2000×2500 | 12.5 |

8×6000 | 8 | 6000 | 100 | 600 | 0.5-2 | 7 | 15 | 6805×2115×2715 | 19.8 |

10×2500 | 10 | 2500 | 120 | 600 | 0.5-2.3 | 10 | 15 | 3195×1800×2210 | 8.2 |

10×3200 | 10 | 3200 | 120 | 600 | 0.5-2.3 | 8 | 15 | 3895×1800×2240 | 9.15 |

10×4000 | 10 | 4000 | 120 | 600 | 0.5-2.3 | 6 | 15 | 1695×1930×2275 | 11 |

10×5000 | 10 | 5000 | 120 | 600 | 0.5-2.3 | 5 | 15 | 5905×2115×2715 | 16 |

10×6000 | 10 | 6000 | 120 | 600 | 0.5-2.3 | 5 | 15 | 6905×2215×2800 | 22 |

12×2500 | 12 | 2500 | 120 | 600 | 0.5-2.3 | 10 | 15 | 3195×1800×2100 | 8.7 |

12×3200 | 12 | 3200 | 120 | 600 | 0.5-2.3 | 8 | 15 | 3895×1800×2240 | 9.8 |

12×4000 | 12 | 4000 | 120 | 600 | 0.5-2.3 | 6 | 15 | 4710×1950×2485 | 13.4 |

12×12000 | 12 | 12000 | 150 | 1000 | 0.5-3 | 5 | 75 | 12780×3800×4400 | 110 |

12×6000 | 12 | 6000 | 120 | 600 | 0.5-2.3 | 4 | 18.5 | 7000×2300×3100 | 29 |

16×2500 | 16 | 2500 | 120 | 600 | 0.5-2.3 | 8 | 15 | 3215×1880×2340 | 9 |

16×3200 | 16 | 3200 | 120 | 600 | 0.5-2.3 | 7 | 15 | 3915×1880×2445 | 11 |

16×4000 | 16 | 4000 | 120 | 600 | 0.5-2.3 | 6 | 15 | 4715×1950×2590 | 15 |

16×5000 | 16 | 5000 | 120 | 600 | 0.5-3 | 5 | 22 | 6000×2300×3000 | 23 |

16×6000 | 16 | 6000 | 120 | 600 | 0.5-3 | 4 | 37 | 7000×2300×3100 | 36 |

20×2500 | 20 | 2500 | 120 | 600 | 0.5-3 | 6 | 22 | 3215×1890×2465 | 11 |

20×3200 | 20 | 3200 | 120 | 600 | 0.5-3 | 5 | 30 | 4120×2890×2780 | 18 |

20×4000 | 20 | 4000 | 120 | 600 | 0.5-3 | 4 | 30 | 4925×2150×2900 | 21 |

20×5000 | 20 | 5000 | 120 | 600 | 0.5-3 | 4 | 37 | 6000×2300×3050 | 29 |

25×2500 | 25 | 2500 | 120 | 600 | 0.5-3.5 | 5 | 30 | 3435×2000×2710 | 15.3 |

25×3200 | 25 | 3200 | 120 | 600 | 0.5-3.5 | 5 | 30 | 4120×2200×3000 | 21 |

25×4000 | 25 | 4000 | 120 | 600 | 0.5-3.5 | 3 | 30 | 4950×2200×3150 | 26 |

30×2500 | 30 | 2500 | 120 | 600 | 1-3.5 | 4 | 30 | 3135×2020×2770 | 17 |

30×3200 | 30 | 3200 | 120 | 600 | 1-3.5 | 3 | 37 | 4200×2300×3200 | 23 |

40X2500 | 40 | 2500 | 120 | 1000 | 0.5-4 | 3 | 55 | 3300x2180x2730 | 27 |

Note: If the parameters in this table do not match the machine tool data, the actual data of the machine tool should prevail. Our company reserves the right of final interpretation.

邮件咨询