- Home

-

Abouts

-

Products

- Plate Shears Series

- Bending Machine Series

- Rolling Machine Series

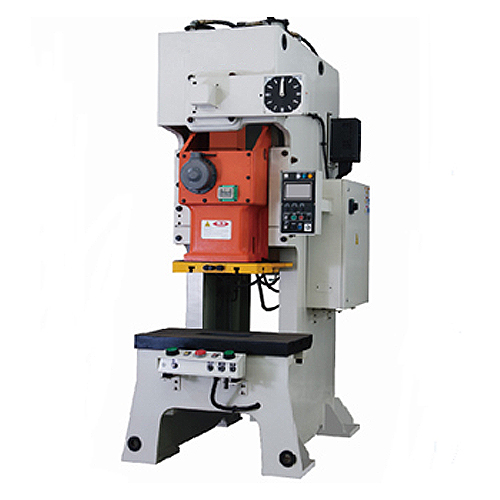

- Mechanical press

- Hydraulic press

- High performance press

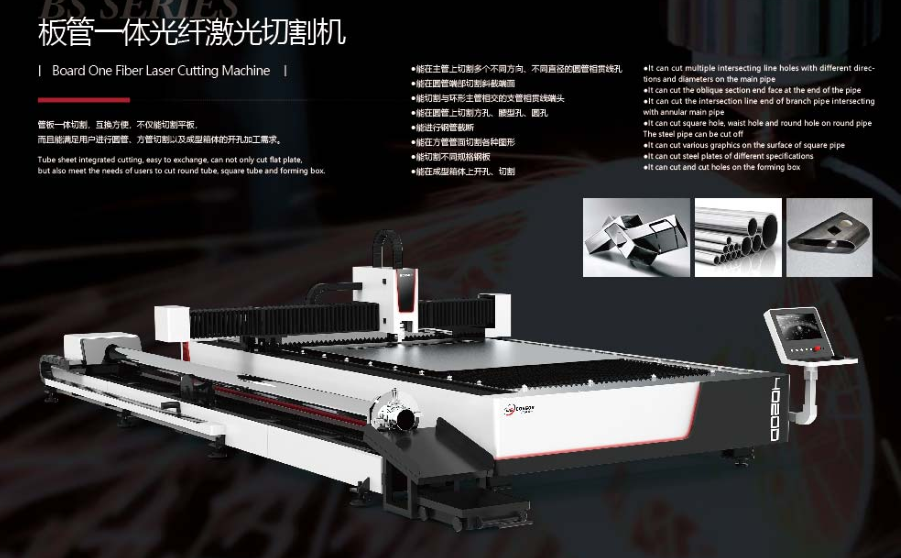

- Optical fiber laser cutting machine

- Combined punching and shearing machine

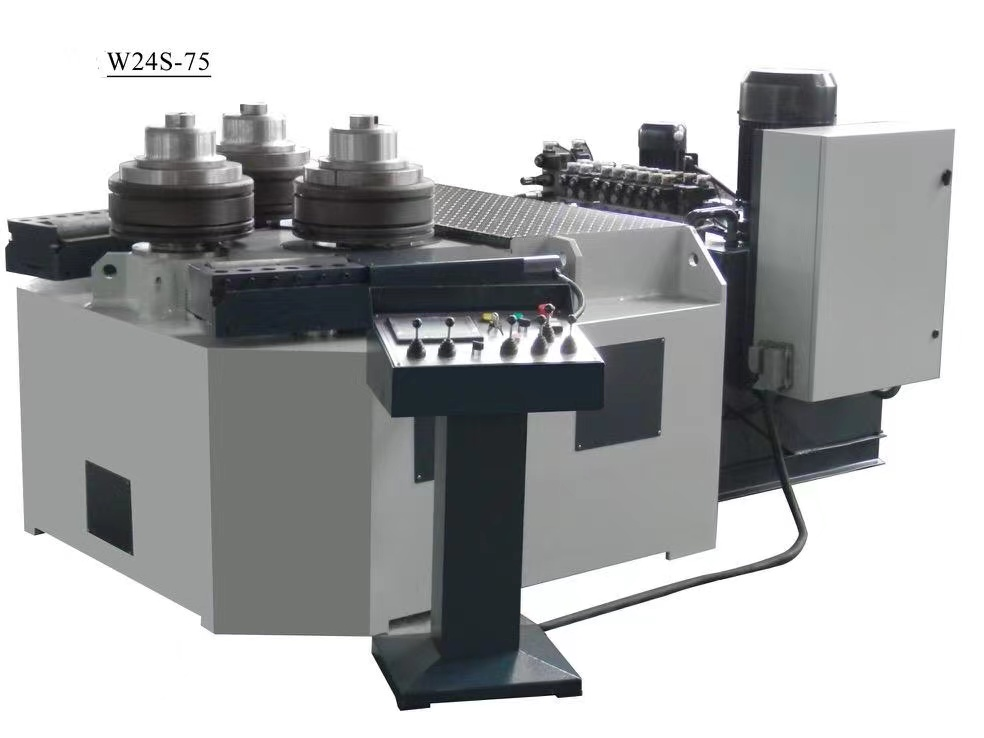

- Profile bender pipe bender

- Grooving machine series

- Tool and mold series

- Cold-Frame Bender

- Shearing machine

- leveling machine

- Biting machine

- Plate rolling machine

-

News

-

Partner

-

Contacts

-

CN

CN

JH21A open single axis steel frame press machine

Send Email

Structure and characteristics:

The JH21A series open fixed table press is developed and produced by our company (formerly Shanghai Second Forging Machine Tool Factory) by introducing advanced technology from both domestic and foreign sources

The universal single axis high-performance press machine has a more complete product structure and has become an increasing production and sales force

The product is suitable for various stamping process lines such as automated wiring and peripheral product combination punching, material dropping, etc.

Performance characteristics:

1. The electrical system adopts a human-machine interface, controlled by the Japanese Omron programmable logic controller (PLC),

Touchscreen is a leading domestic brand of "Weilun", and the machine tool operates with variable speed drives. The machine tool has emergency stop

Inching, single and continuous, pre fabricated counting and peripheral equipment connection work operation modes; main

All electrical components are from the French brand Schneider, with reliable performance.

2. The clutch dual valve is selected from the Japanese brand "TACO", and the pneumatic two-piece is from the "Yadeke" brand,

Reliable performance. 3. The body is made of high-quality steel plate CNC cutting and CO2 welded structure, with good overall rigidity and beautiful appearance;

The body adopts trolley type electric furnace annealing or vibration aging methods to remove stress, with minimal deformation. The crankshaft is placed longitudinally,

Short pivot distance, compact structure, and reasonable layout. The transmission gear operates immersed in oil in the gearbox, as indicated by the gear gauge

Surface grinding treatment results in low noise and minimal wear during transmission operation.

4. Pneumatic friction clutch brake, mechanical interlocking, safe and reliable, low noise, and friction plates are not easily worn; Choose domestic Shanghai "Dingjie" brand clutch or Italian "OMPI" brand clutch; And provide wet clutches according to the special needs of users.

5. Select imported pneumatic external hydraulic overload pump, which has sensitive response, good stability, and easy maintenance.

6. The slider guide rail adopts six sided guidance, with a long guide rail and high operating accuracy.

7. The lubrication system adopts imported electric grease pump for automatic fixed-point lubrication, and is equipped with a progressive distributor for oil supply

The time and fuel supply are controlled by the PLC system, and automatic alarm indication is given for oil circuit blockage.

8. The slider mold height adjustment is convenient to use, and it is equipped with a digital mold height indicator with a display accuracy of+0.1mm.

(Note: Manual adjustment for JH21B-60 and below, electric adjustment for JH21B-80 and above).

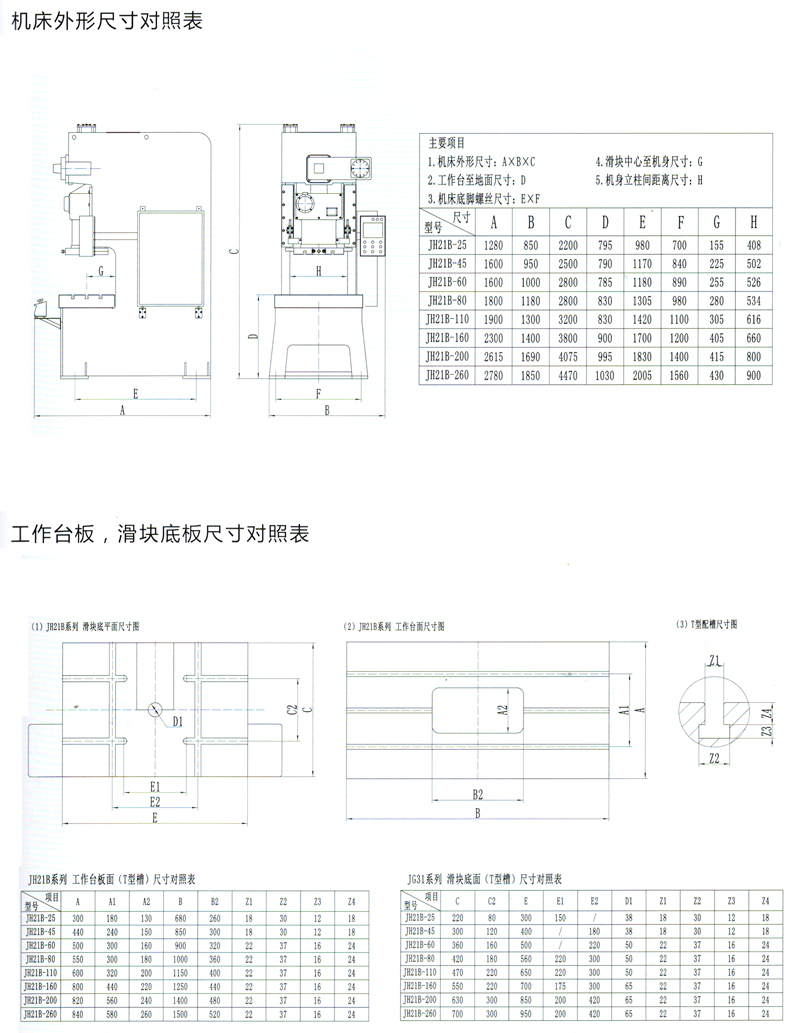

Main technical parameters of JH21A open single axis steel frame press machine

Specification/Model | JH21B-25 | JH21B-45 | JH21B-60 | JH21B-80 | JH21B-110 | JH21B-160 | JH21B-200 | JH21B-260 | ||||||||

V型 | H型 | V型 | H型 | V型 | H型 | V型 | H型 | V型 | H型 | V型 | H型 | V型 | H型 | V型 | H型 | |

tonnage(T) | 25 | 45 | 60 | 80 | 110 | 160 | 200 | 260 | ||||||||

Location of impulse occurrence(mm) | 3.2 | 1.6 | 3.2 | 1.6 | 4 | 2 | 4 | 2 | 6 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 |

Variable speed per minute s.p.c | 60-140 | 130-200 | 40-100 | 110-150 | 35-90 | 80-120 | 35-80 | 80-120 | 30-60 | 60-90 | 20-50 | 40-70 | 20-50 | 50-70 | 20-40 | 40-50 |

Fixed speed for the number of trips s.p.c | 140 | 200 | 100 | 150 | 90 | 120 | 80 | 120 | 60 | 90 | 50 | 70 | 50 | 70 | 40 | 50 |

trip(mm) | 60 | 30 | 80 | 50 | 120 | 60 | 150 | 70 | 180 | 80 | 200 | 90 | 200 | 100 | 250 | 150 |

Maximum closed working height mm | 200 | 215 | 250 | 265 | 310 | 340 | 340 | 380 | 360 | 410 | 460 | 510 | 460 | 510 | 500 | 550 |

Adjustment number of lubrication block mm | 50 | 60 | 75 | 80 | 80 | 100 | 110 | 120 | ||||||||

Size of the upper workbench(mm) | 300*220*50 | 400*300*60 | 500*360*70 | 560*420*70 | 650*470*80 | 700*550*90 | 850*630*90 | 950*700*100 | ||||||||

Lower workbench size(mm) | 680*300*70 | 850*440*80 | 900*500*80 | 1000*550*90 | 1000*600*110 | 1250*800*140 | 1400*820*160 | 1500*840*180 | ||||||||

Handle hole(mm) | 38.1 | 38.1 | 50 | 50 | 50 | 65 | 65 | 65 | ||||||||

main motor(KW) | 2.2-4P | 4-4P | 5.5-4P | 7.5-4P | 11-4P | 15-4P | 18.5-4P | 22-4P | ||||||||

Slider adjustment mechanism(HP) | 手动 | 电动 | ||||||||||||||

Use air pressure kg/cm | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | ||||||||

Punching accuracy | GB(JIS)1class一级 | |||||||||||||||

Length * Width * Degree mm | 1280*850 | 1600*950 | 1600*1000 | 1800*1180 | 1900*1300 *3200 | 2300*1400 | 2615*1690 | 2780*1850 | ||||||||

weight(T) | 2.1 | 3.8 | 5.6 | 6.5 | 9.6 | 16 | 23 | 32 | ||||||||

Mold cushion capability(T) | 2.3 | 3.6 | 3.6 | 6.3 | 10 | 14 | 14 | |||||||||

Mold cushion has a long stroke(mm) | 50 | 70 | 70 | 80 | 80 | 100 | 100 | |||||||||

Effective area of mold pad(mm) | 300*230 | 350*300 | 450*310 | 500*350 | 650*420 | 710*480 | 810*480 | |||||||||

Standard configuration:

Dry clutch, hydraulic overload protection device, electric grease lubrication device, manual thin oil lubrication device, slider and upper mold balance device, electronic crankshaft angle indicator

Cam controller, electric slider adjustment device, air source quick connector, programmable controller, slider upper material removal device, touch screen shock-absorbing pad, air blowing, dual solenoid valve

Selection configuration: (User selection should be specified in the contract)

Wet clutch brake, pneumatic mold pad device, photoelectric safety device, quick mold changing device, foot switch, automatic feeding output shaft, speed regulating motor, variable frequency speed regulation

Preset counter

Email Consultation