- Home

-

Abouts

-

Products

- Plate Shears Series

- Bending Machine Series

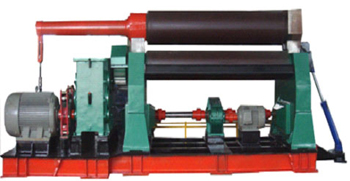

- Rolling Machine Series

- Mechanical press

- Hydraulic press

- High performance press

- Optical fiber laser cutting machine

- Combined punching and shearing machine

- Profile bender pipe bender

- Grooving machine series

- Tool and mold series

- Cold-Frame Bender

- Shearing machine

- leveling machine

- Biting machine

- Plate rolling machine

-

News

-

Partner

-

Contacts

-

CN

CN

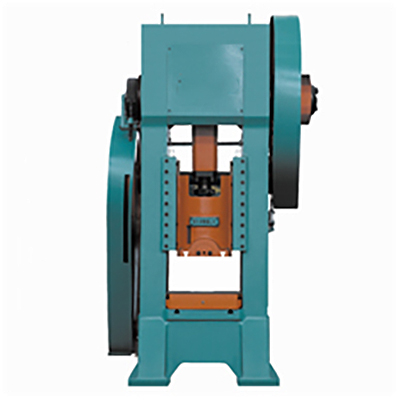

J31 closed single point press

Send Email

Performance characteristics:

1. The machine body is of casting or steel plate structure, linear design, uniform stress, good rigidity and beautiful appearance; Low temperature tempering is used for stress relief.

2. The crankshaft is laid horizontally, and the transmission system is placed on both sides of the machine body. The structure is compact, the layout is reasonable, and the transmission is stable.

3. The rotary key type rigid clutch is adopted, with reliable performance and sensitive action.

4. It is guided by four sided guide rails, with high running accuracy and effectively prolonging the service life of the die.

5. Belt brake, there is a collapse type safety block in the slider to ensure the safety of the press; The structure is simple and convenient for maintenance.

6. Above 200T, pneumatic double balance structure is adopted to balance the weight of sliding block and upper mold, so that the press can run stably.

7. The centralized and decentralized lubrication system is adopted, which is economical and reliable, and ensures that there is sufficient oil in all lubrication parts.

8. The extra large frame with external support improves the stability and safety of machine tool installation and operation.

Main technical parameters of J31 closed single point press:

Technical Parameter | 单位 | J31-100 | J21-125 | J21-1600 | J31-200 | J31-250 | J31-315 | |

Sliding block nominal pressure | KN | 1000 | 1250 | 1600 | 2000 | 2500 | 3150 | |

Rated toque journey | mm | 10 | 10 | 10 | 12 | 12 | 13 | |

Slide stroke | mm | 165 | 165 | 180 | 210 | 230 | 250 | |

Stroke times | 次/min | 35 | 35 | 35 | 35 | 35 | 26 | |

Maximum enclosed height | mm | 285 | 370 | 500 | 550 | 600 | 600 | |

Adjustment of mold height | mm | 100 | 100 | 100 | 120 | 125 | 125 | |

Distance between columns | mm | 660 | 685 | 700 | 720 | 820 | 820 | |

Workbench size | around | mm | 620 | 650 | 680 | 850 | 900 | 1000 |

about | mm | 620 | 650 | 660 | 700 | 720 | 800 | |

Diameter | mm | 250 | 250 | 250 | 320 | 300 | 300 | |

Slide bottom plane size | around | mm | 300 | 360 | 360 | 480 | 500 | 540 |

about | mm | 360 | 380 | 380 | 480 | 500 | 540 | |

Mold handle hole size | Diameter | mm | 65 | 65 | 65 | 70 | 70 | 80 |

depth | mm | 120 | 110 | 110 | 110 | 110 | 110 | |

External dimensions | around | mm | 1780 | 1745 | 1635 | 1975 | 2100 | 2460 |

about | mm | 1670 | 1670 | 1880 | 2030 | 2440 | 2440 | |

tall | mm | 2780 | 2915 | 3130 | 3550 | 4000 | 4180 | |

Pad thickness | mm | 90 | 90 | 110 | 140 | 140 | 150 | |

power | KW | 7.5 | 7.5 | 15 | 22 | 30 | 30 | |

weight | kg | 5230 | 6000 | 8000 | 11000 | 12500 | 16500 | |

Note: If the parameters in this table are inconsistent with the machine tool data, the actual data of the machine tool shall prevail. The Company reserves the right of final interpretation.

Email Consultation