- Home

-

Abouts

-

Products

- Plate Shears Series

- Bending Machine Series

- Rolling Machine Series

- Mechanical press

- Hydraulic press

- High performance press

- Optical fiber laser cutting machine

- Combined punching and shearing machine

- Profile bender pipe bender

- Grooving machine series

- Tool and mold series

- Cold-Frame Bender

- Shearing machine

- leveling machine

- Biting machine

- Plate rolling machine

-

News

-

Partner

-

Contacts

-

CN

CN

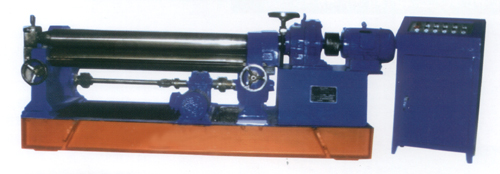

JS36 Closed Double Point High Performance Press

Send Email

Structure and Characteristics

The JS36 series closed double point press is a super large closed double point press machine produced by our company (formerly Shanghai Second Forging Machine Tool Factory) by introducing advanced domestic and foreign technologies and optimizing the combination production. It has a wide range of applications in the fields of automotive parts, large sheet metal, and progressive die stamping production, and is suitable for various processes such as punching, cutting, bending, and shallow stretching of large and wide face materials.

Performance characteristics:

1. The eccentric herringbone large gear structure slider has a large operating stroke, large capacity occurrence point, high sealing height, and high punching force, and can punch large structural components.

2. The body is a split structure consisting of a top seat, a middle platform, and a base, which is convenient for transportation and installation. The structural components are made of high-quality steel plate CNC cutting and CO2 welded structure, with good overall rigidity and beautiful appearance; Structural components undergo annealing or vibration aging to remove stress, resulting in minimal deformation. The split structure is symmetrical in front and back, greatly improving the accuracy of stamping parts and the service life of molds.

3. Configure a hydraulic mobile workbench for easy installation and debugging of large molds.

4. Two intermediate shafts are placed longitudinally, with short pivot distance, compact structure, and reasonable layout. The unique synchronous reversal method eliminates the lateral force of the slider on the guide rail and the body, with strong resistance to eccentric load and smooth operation.

5. The surface of the herringbone gear on the transmission shaft is processed with high precision, resulting in low noise and minimal wear during transmission operation.

6. Pneumatic friction clutch brake, mechanical interlocking, safe and reliable, low noise, and friction plates are not easily worn; Choose the Italian brand "OMPI" clutch; And provide wet clutches according to the special needs of users.

7. Imported pneumatic external hydraulic overload pump is selected, with sensitive response, good stability, and easy maintenance.

8. The lubrication system adopts imported electric circulation lubrication and is equipped with a progressive distributor, controlled by a PLC system, with automatic alarm indication for oil circuit blockage.

9. The slider is equipped with an electric mode height adjustment, which is easy to use, and is also equipped with a digital mode height indicator with a display accuracy of+0.1mm.

10. Configure a pneumatic balancing device to balance the weight of the slider and upper mold, ensuring smooth operation of the press.

11. The electrical system is controlled by the French brand Schneider and the Japanese brand Izumi programmable logic controller (PLC), with stepless speed regulation for the number of strokes, and features emergency stop, inching, single time, and continuous operation modes; The main electrical components are all from the French brand Schneider, with reliable performance.

Main technical parameters of JS36 closed double point high-performance press

model | unit | JS36-400A | JS36-500 | JS36-630 | JS36-630A | JS36-800 | JS36-1600 | JS36-2500 | |

Nominal force | KN | 4000 | 5000 | 6300 | 6300 | 8000 | 16000 | 25000 | |

Rated toque journey | mm | 13 | 13 | 13 | 13 | 13 | 13 | 13 | |

Slide stroke length | mm | 400 | 500 | 500 | 500 | 500 | 500 | 500 | |

Number of slider strokes | 次/min | 16 | 14 | 14 | 14 | 10 | 10 | 8 | |

Maximum Die Set Height | mm | 770 | 900 | 1100 | 1400 | 990 | 950 | 950 | |

Adjustment of mold height | mm | 400 | 500 | 500 | 700 | 400 | 400 | 400 | |

Workbench dimensions (front and back * left and right) | mm | 1600*2800 | 1600*3500 | 1800*3500 | 1800*3500 | 1800*3640 | 2000*5000 | 1800*7400 | |

Bottom size of slider (front to back * left to right) | mm | 1300*2800 | 1600*3500 | 1800*3500 | 1800*3500 | 1800*3640 | 2000*5000 | 1800*7400 | |

air cushion | Compression force/withdrawal force | KN | 600/600 | 1000 | 1000 | 1000 | 1000 | 3000 | 3300 |

number | 2 | Single crown | Single crown | Single crown | Single crown | Single crown | 6 | ||

trip | mm | 200 | 0-250 | 0-250 | 0-250 | 0-2000 | 200 | 250 | |

Sliding block feeding | type | rigidity | rigidity | pneumatic | pneumatic | pneumatic | pneumatic | pneumatic | |

Material feeding power | KN | 150 | 150 | 150 | 150 | 150 | 100 | 100 | |

Main motor power | KW | 45 | 90 | 90 | 90 | 110 | 132 | 160 | |

The height above the ground of the press machine | mm | 7000 | 7400 | 7980 | 8140 | 9600 | 10100 | 10250 | |

Dimensions of the press machine (front and rear * left and right) | mm | 4000*5100 | 4200*5200 | 4460*6040 | 4700*6140 | 5100*8100 | 5600*8500 | 5800*10300 | |

Weight of the entire press machine | T | 104 | 174 | 203 | 205 | 250 | 480 | 680 | |

Standard configuration:

Dry clutch, hydraulic overload protection device, electric grease lubrication device, manual thin oil lubrication device, slider and upper mold balance device, electronic crankshaft angle indicator

Electronic cam controller, electric slider adjustment device, programmable controller, upper slider discharge device, air source quick connector, dual solenoid valve, movable dual hand operation platform

Shock pad, air blown material, frequency converter, movable electrical control box.

Selection configuration: (User selection should be specified in the contract)

Wet clutch brake, pneumatic mold pad device, photoelectric safety device, quick mold changing device, foot switch, automatic feeding output shaft, preset counter

Email Consultation