- Home

-

Abouts

-

Products

- Plate Shears Series

- Bending Machine Series

- Rolling Machine Series

- Mechanical press

- Hydraulic press

- High performance press

- Optical fiber laser cutting machine

- Combined punching and shearing machine

- Profile bender pipe bender

- Grooving machine series

- Tool and mold series

- Cold-Frame Bender

- Shearing machine

- leveling machine

- Biting machine

- Plate rolling machine

-

News

-

Partner

-

Contacts

-

CN

CN

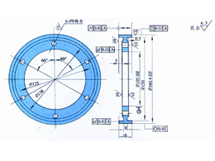

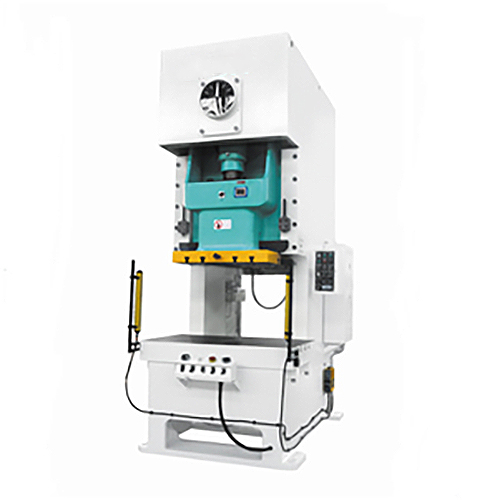

J23 open type tilting press

Send Email

Structure and characteristics

J23 series press is our company's traditional product with a long history. The product is stable and durable. The machine body can be tilted to facilitate blanking. The machine tool is simple to operate and maintain. It is suitable for punching, blanking, bending, shallow stretching and other processes.

Performance characteristics:

1. The machine body is of casting structure, which is subject to artificial aging treatment, with small deformation and can be tilted.

2. The rotary key type rigid clutch is adopted, with simple structure, no air supply, reliable performance and sensitive action.

3. The crankshaft is laid horizontally, with compact structure, reasonable layout and stable transmission.

4. The sliding block is guided by V-shaped guide rail with high operation accuracy; The guide rail surface is quenched, with high hardness, improving accuracy and service life.

5. Collapse type safety block is adopted, with reliable action to ensure safe production of the press; The structure is simple and convenient for maintenance.

6. The height of the sliding block can be adjusted for easy use.

Technical parameters of J23 open type tilting press

model | 6.3 | 10 | 16 | 20 | 25 | 35 | 40 | 63 | 80 | 100 | unit | |

Nominal force | 63 | 100 | 160 | 200 | 250 | 350 | 400 | 630 | 800 | 1000 | KN | |

Slide stroke | 35 | 60 | 70 | 90 | 90 | 100 | 100 | 120 | 120 | 130 | mm | |

Stroke times | 170 | 145 | 120 | 90 | 100 | 53 | 55 | 50 | 50 | 45 | s.m.p | |

Maximum enclosed height | 150 | 180 | 220 | 250 | 250 | 205 | 300 | 360 | 360 | 400 | mm | |

Closed height adjustment amount | 30 | 50 | 60 | 70 | 70 | 100 | 80 | 90 | 90 | 100 | mm | |

throat depth | 110 | 130 | 160 | 175 | 190 | 205 | 240 | 260 | 260 | 320 | mm | |

Distance between columns | 145 | 185 | 220 | 240 | 260 | 295 | 300 | 350 | 350 | 450 | mm | |

Workbench size | about | 310 | 360 | 450 | 500 | 560 | 610 | 700 | 710 | 720 | 900 | mm |

around | 200 | 240 | 300 | 330 | 360 | 380 | 460 | 480 | 500 | 600 | mm | |

Workbench thickness | 35 | 50 | 60 | 70 | 70 | 70 | 80 | 90 | 90 | 110 | mm | |

Bottom size of slider | about | 140 | 170 | 200 | 220 | 250 | 255 | 320 | 320 | 320 | 390 | mm |

around | 120 | 150 | 180 | 200 | 210 | 210 | 270 | 280 | 280 | 340 | mm | |

Mold handle hole size | diameter | Φ30 | Φ30 | Φ40 | Φ40 | Φ40 | Φ40 | Φ50 | Φ50 | Φ50 | Φ50 | mm |

depth | 55 | 55 | 60 | 60 | 60 | 60 | 70 | 80 | 80 | 80 | mm | |

power | 0.75 | 1.1 | 1.5 | 2.2 | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | KW | |

External dimensions | around | 78 | 87 | 114 | 120 | 135 | 148 | 150 | 181 | 188 | 220 | cm |

about | 55 | 64 | 90.5 | 88 | 95 | 105.2 | 118 | 140 | 148 | 150 | cm | |

height | 150 | 166 | 189 | 200 | 213 | 214.5 | 230 | 275 | 282 | 318 | cm | |

weight | 400 | 770 | 1070 | 1400 | 1600 | 2500 | 3500 | 5000 | 6000 | 9000 | kg | |

Note: If the parameters in this table are inconsistent with the machine tool data, the actual data of the machine tool shall prevail. The Company reserves the right of final interpretation

Email Consultation