- 网站首页

-

Abouts

-

Products

- Plate Shears Series

- Bending Machine Series

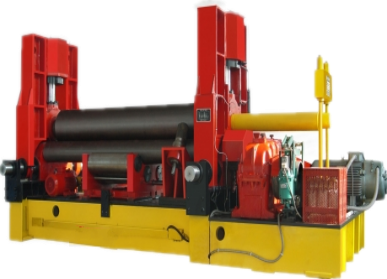

- Rolling Machine Series

- Mechanical press

- Hydraulic press

- High performance press

- Optical fiber laser cutting machine

- Combined punching and shearing machine

- Profile bender pipe bender

- Grooving machine series

- Tool and mold series

- Cold-Frame Bender

- Shearing machine

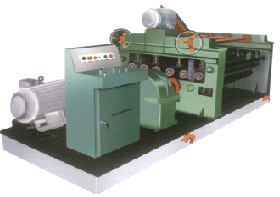

- leveling machine

- Biting machine

- Plate rolling machine

-

News

-

Partner

-

Contacts

-

EN

EN

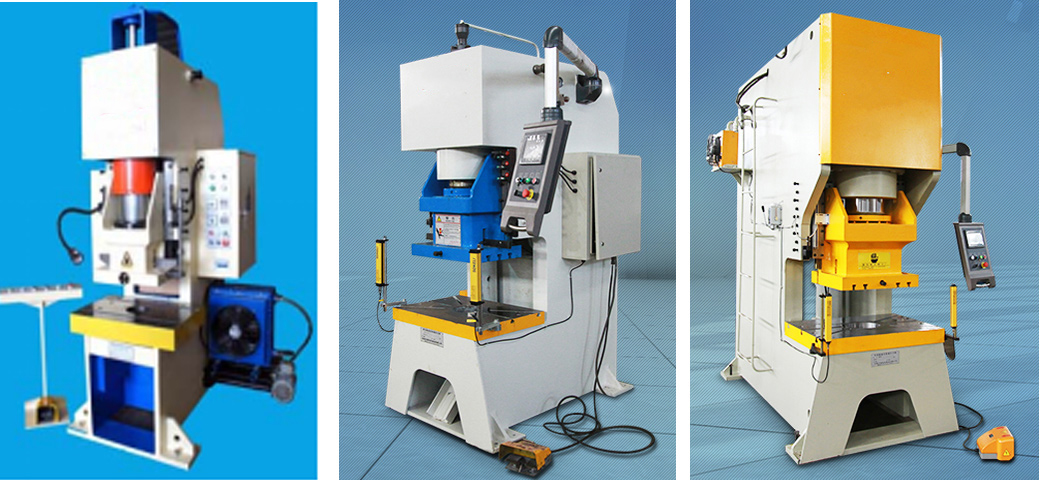

Y27Y Hydraulic Quick Press

Send Email

Performance Characteristics:

This series of machine tool are applicable to blanking, stretch, and pressing processes of plastic materials, such as blanking, bending, flanging, sheet stretch and fine blanking of sheet metal and cold extruding of metal parts. They are also applicable to calibrating and press-fitting of grinding wheel for its forming, and compression molding of plastic products and powder products.

This machine uses hydraulic transmission mode, with advantages of hydraulic machine and mechanical press, able to alter the pressing power at random, without generating overload, and also able to meet the pressure maintaining and time delay requirements of the actions during pressing process. For the purpose of realizing slider fast air-way down and fast back stroke, speed up cylinder is used for the machine tool, which automatically changes into slow work upon contacting the machine parts. Therefore, the discharge capacity of the necessary oil pump, motor capacity and noise are all reduced.Photo-electric safety device can be installed in the front of workbench, to form protective barrier above the workbench, in order to ensure personal safety of the operator. The integrated button on machine tool can realize three kinds of operation modes: adjustable, semi-automatic and automatic. To sum up, this machine has advantages of novel structure, reliable performance, complete functions and high production efficiency, making it a replacement product for mechanical press.

Main Technical Parameters of Y27Y Hydraulic Quick Press

Specifications and Model | Company | 25 | 40 | 50 | 63 | 80 | 100 | 125 | 160 | 200 | 250 | 300 | |

Nominal Pressure | KN | 250 | 400 | 500 | 630 | 800 | 1000 | 1250 | 1600 | 2000 | 2500 | 3000 | |

Maximum Working Pressure of Liquid | mpa | 22 | 21 | 21 | 20 | 21.5 | 22.5 | 25 | 25 | 25 | 25 | 25 | |

Maximum Journey of Slider | mm | 130 | 130 | 130 | 150 | 180 | 180 | 220 | 220 | 220 | 220 | 200 | |

Slider Working Times | 1/min | 10-50 | 10-50 | 10-50 | 10-40 | 10-40 | 10-40 | 10-30 | 10-30 | 10-30 | 10-30 | 10-30 | |

Maximum Shut Height | mm | 315 | 320 | 320 | 445 | 470 | 470 | 520 | 520 | 520 | 520 | 700 | |

Journey Adjustment | mm | 130 | 130 | 130 | 150 | 180 | 180 | 220 | 110 | 110 | 110 | 200 | |

Depth of Throat | mm | 210 | 235 | 235 | 260 | 310 | 310 | 350 | 350 | 400 | 350 | 350 | |

Height of Workbench from Floor | mm | 740 | 740 | 740 | 750 | 770 | 770 | 870 | 920 | 920 | 1020 | 1020 | |

Approach Speed | mm/s | 225 | 265 | 265 | 220 | 220 | 210 | 250 | 230 | 230 | 200 | 150 | |

Work Speed | mm/s | 18 | 14 | 14 | 18 | 17 | 14 | 16 | 10 | 10 | 6 | 6 | |

Return Speed | mm/s | 99 | 118 | 118 | 195 | 195 | 195 | 200 | 170 | 170 | 100 | 100 | |

Size of Slider Undersurface | Left and Right | mm | 250 | 320 | 320 | 440 | 500 | 500 | 600 | 600 | 700 | 680 | 1600 |

Front and Back | mm | 220 | 270 | 270 | 320 | 350 | 350 | 500 | 500 | 580 | 540 | 600 | |

Die Hole | mm | Φ40 | Φ50 | Φ50 | Φ50 | Φ60 | Φ60 | Φ60 | Φ60 | Φ65 | Φ70 | Φ70 | |

Size of Workbench | Left and Right | mm | 600 | 630 | 630 | 710 | 850 | 850 | 1000 | 1000 | 1300 | 1300 | 1700 |

Front and Back | mm | 400 | 450 | 450 | 500 | 600 | 600 | 650 | 650 | 740 | 740 | 750 | |

Pore Diameter | mm | Φ100 | Φ150 | Φ150 | Φ150 | Φ180 | Φ180 | Φ200 | Φ200 | Φ200 | Φ200 | Φ200 | |

Outline dimension | Left and Right | mm | 1160 | 1100 | 1100 | 1250 | 1370 | 1350 | 1600 | 1700 | 1800 | 1900 | 2000 |

Front and Back | mm | 1155 | 1260 | 1260 | 1450 | 1630 | 1630 | 1850 | 2000 | 2100 | 2200 | 2300 | |

height | mm | 1900 | 1980 | 1980 | 2270 | 2500 | 2500 | 3400 | 3500 | 3600 | 3700 | 3800 | |

Motor Power | kw | 5.5/6 | 5.5/4 | 5.5/4 | 5.5/4 | 7.5/6 | 7.5/6 | 11/6 | 22 | 22 | 22 | 37 | |

Oil Pump | m1/r | 10 | 12 | 12 | 25 | 40 | 40 | 63 | 63 | 80 | 80 | 80 | |

Machine Weight | kg | 2000 | 2600 | 2800 | 3200 | 4800 | 5000 | 8500 | 11000 | 14000 | 22000 | 26000 | |

邮件咨询