- 网站首页

-

Abouts

-

Products

- Plate Shears Series

- Bending Machine Series

- Rolling Machine Series

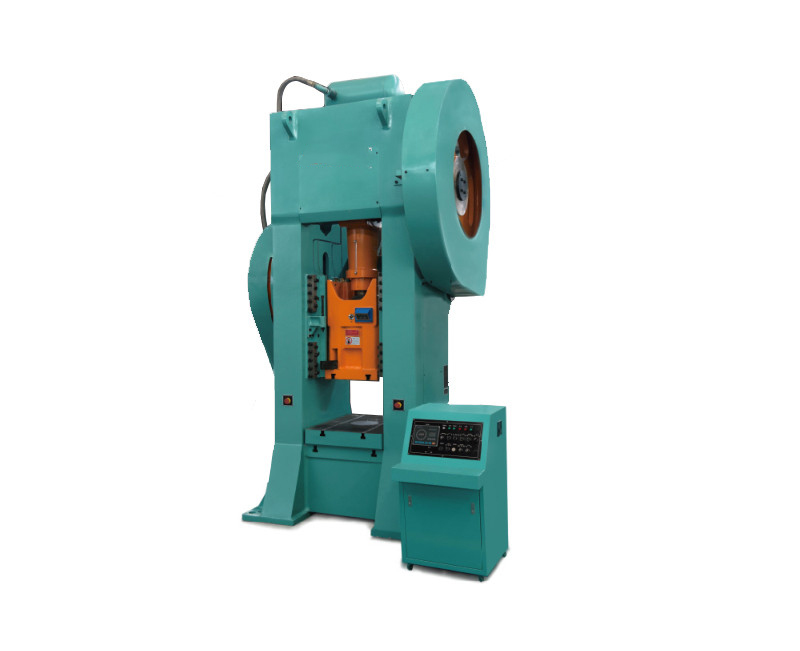

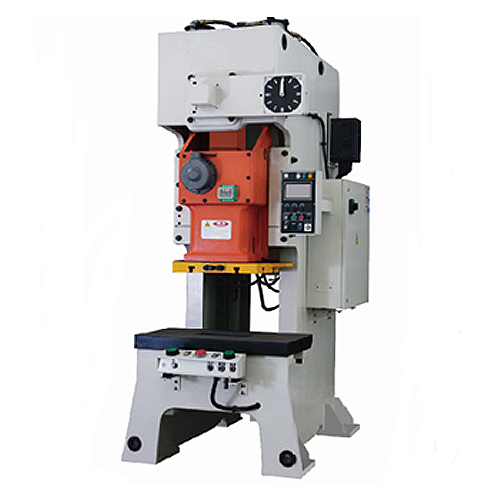

- Mechanical press

- Hydraulic press

- High performance press

- Optical fiber laser cutting machine

- Combined punching and shearing machine

- Profile bender pipe bender

- Grooving machine series

- Tool and mold series

- Cold-Frame Bender

- Shearing machine

- leveling machine

- Biting machine

- Plate rolling machine

-

News

-

Partner

-

Contacts

-

EN

EN

W11SNC Top roll universal three roll plate bending machine

Send Email

Performance characteristics

This machine belongs to the hydraulic three roll plate rolling machine, which is used to roll the steel plate into a cylinder under normal temperature. The upper roll can move vertically and horizontally. Pre bending is realized by moving the upper roll horizontally, so that the upper roll is in an asymmetric position relative to the lower roll. The two lower rollers are driven by the motor and reducer during rounding. Since the elevation of the lower roll remains unchanged, it is convenient for feeding and operation. The longitudinal alignment device is provided to reduce the unfitness of the product during the coiling process. PLC control is adopted, and roller displacement is displayed digitally.

Drum shape, upper roll and lower idler of lower roll are adjusted together, and the straightness of high-precision products is drum shape The drum preset amount of the upper roll and the upper roll is usually 70% of the uniform load of the roll. For the lower roll with smaller diameter, the lower part of the lower roll is supported by an adjustable upper and lower idler. According to the load of the rolled products, the supporting roller at the lower part of the lower roller is adjusted to greatly improve the straightness of the products. Rear bending and coiling, high-precision product roundness The upper roll coiler adopts rear bending (the direction of plate feeding is opposite to the moving direction of the upper roll), the upper roll presses down while the lower roll rotates, and continuously bends. The pre bending of the end of the plate directly pressurizes the pre bending, which avoids the generation of the angle after the front bending, and can control the length and shape of the remaining straight edges.

Technical Parameters of W11SNC Top Roll Universal Three roll Plate Bending Machine

Specification and model | Maximum roll thickness(mm) | Maximum pre bending thickness(mm) | Maximum roll width(mm) | Upper roller pressure (ton) | Minimum diameter at full load(mm) | Upper roller diameter (mm) | Lower roller diameter (mm) | Center distance between two rollers(mm) | power(KW) | ||

Roller rotation | hydraulic pressure system | Lower roller move | |||||||||

6×2000 | 6 | 4.5 | 2000 | 25 | 380 | 205 | 125 | 160 | 3 | 2.2 | 1.1 |

8×2000 | 8 | 6 | 2000 | 35 | 450 | 220 | 135 | 180 | 4 | 2.2 | 1.1 |

8×2500 | 8 | 6 | 2500 | 37 | 500 | 240 | 135 | 180 | 5.5 | 4 | 2.2 |

12×2000 | 12 | 9 | 2000 | 65 | 500 | 255 | 150 | 245 | 7.5 | 4 | 1.1 |

12×2500 | 12 | 9 | 2500 | 75 | 650 | 300 | 160 | 270 | 11 | 5.5 | 2.2 |

12×3000 | 12 | 9 | 3000 | 100 | 750 | 320 | 180 | 300 | 15 | 5.5 | 2.2 |

16×2000 | 16 | 12 | 2000 | 75 | 650 | 300 | 160 | 270 | 11 | 5.5 | 2.2 |

16×2500 | 16 | 12 | 2500 | 100 | 750 | 320 | 180 | 300 | 15 | 5.5 | 2.2 |

16×3200 | 16 | 12 | 3200 | 130 | 850 | 380 | 200 | 330 | 22 | 7.5 | 4 |

20×2000 | 20 | 16 | 2000 | 100 | 750 | 320 | 180 | 300 | 15 | 5.5 | 2.2 |

20×2500 | 20 | 16 | 2500 | 130 | 850 | 380 | 220 | 360 | 22 | 7.5 | 4 |

20×3000 | 20 | 16 | 3000 | 190 | 950 | 410 | 230 | 380 | 30 | 7.5 | 4 |

25×2000 | 25 | 20 | 2000 | 130 | 850 | 380 | 220 | 360 | 22 | 7.5 | 4 |

25×2500 | 25 | 20 | 2500 | 190 | 950 | 410 | 230 | 380 | 30 | 7.5 | 4 |

25×3200 | 25 | 20 | 3200 | 240 | 1100 | 460 | 260 | 420 | 37 | 11 | 4 |

30×2000 | 30 | 25 | 2000 | 190 | 950 | 410 | 230 | 380 | 30 | 7.5 | 4 |

30×2500 | 30 | 25 | 2500 | 270 | 1100 | 460 | 260 | 420 | 37 | 11 | 4 |

30×3200 | 30 | 25 | 3200 | 320 | 1400 | 510 | 260 | 460 | 45 | 15 | 4 |

30×4000 | 30 | 25 | 4000 | 450 | 1600 | 590 | 280 | 500 | 45 | 15 | 5.5 |

40×2000 | 40 | 32 | 2000 | 270 | 1200 | 480 | 260 | 420 | 37 | 11 | 4 |

40×2500 | 40 | 32 | 2500 | 320 | 1400 | 520 | 290 | 500 | 55 | 15 | 4 |

40×3200 | 40 | 32 | 3200 | 450 | 1600 | 560 | 290 | 500 | 55 | 15 | 5.5 |

40×4000 | 40 | 32 | 4000 | 550 | 2000 | 660 | 360 | 650 | 75 | 22 | 7.5 |

52×2500 | 52 | 40 | 2500 | 450 | 1800 | 610 | 320 | 580 | 55 | 15 | 5.5 |

52×3200 | 52 | 40 | 3200 | 610 | 2000 | 650 | 380 | 700 | 75 | 22 | 11 |

50×4000 | 50 | 40 | 4000 | 690 | 2000 | 780 | 420 | 800 | 90 | 22 | 11 |

50×5000 | 50 | 40 | 5000 | 800 | 2100 | 850 | 460 | 880 | 90 | 37 | 15 |

60×2500 | 60 | 50 | 2500 | 610 | 2000 | 650 | 380 | 700 | 75 | 30 | 15 |

60×3200 | 60 | 50 | 3200 | 690 | 2000 | 710 | 420 | 780 | 90 | 30 | 15 |

60×4000 | 60 | 50 | 4000 | 800 | 2100 | 840 | 480 | 920 | 110 | 37 | 15 |

60×5000 | 60 | 50 | 5000 | 1050 | 2500 | 940 | 520 | 1000 | 110 | 37 | 22 |

70×3200 | 70 | 60 | 3200 | 1050 | 2000 | 840 | 480 | 920 | 110 | 37 | 15 |

80×4000 | 80 | 70 | 4000 | 1350 | 2500 | 900 | 560 | 1080 | 132 | 45 | 22 |

100×4000 | 100 | 90 | 4000 | 1600 | 3000 | 960 | 600 | 1120 | 160 | 45 | 22 |

Note: If the parameters in this table are inconsistent with the machine tool data, the actual data of the machine tool shall prevail. The Company reserves the right of final interpretation.

邮件咨询